The Best Guide To Sheroz Earthworks

The Best Guide To Sheroz Earthworks

Blog Article

The Buzz on Sheroz Earthworks

Table of ContentsGetting The Sheroz Earthworks To WorkNot known Facts About Sheroz EarthworksHow Sheroz Earthworks can Save You Time, Stress, and Money.The Buzz on Sheroz EarthworksThe 5-Second Trick For Sheroz Earthworks

For any kind of earthwork specialist, it is essential to perform deal with high quality, precision, and on routine. Using machine control in job devices enables optimizing the various phases in the earthwork procedure, from planning to the upkeep stage - trimble gps. The device control system aids the device operator in attaining the target plane swiftly and quicklyThe maker control system overviews the operator with centimeter precision. With Xsite PRO 3D, you'll constantly know specifically exactly how much to reduce or fill up. Your neighborhood Xsite technical assistance can guide you and help with any type of troubles without going to the website. Remote assistance saves money and time, as it decreases downtime in jobsites.

3 Easy Facts About Sheroz Earthworks Described

Added training and instructions are constantly readily available over remote support when needed. The earthmoving industry has used our field-proven services because the very early 1990s. Our system's components are meticulously designed to withstand the harsh conditions of construction websites. Contrast of the same job executed making use of machine control versus the conventional method discloses that, usually, the typical method needs 50% even more time to accomplish the very same task as the technology-assisted approach. https://www.magcloud.com/user/sherozau.

Go into the Xsite maker control system; it's below to supply you with a considerable benefit when functioning with earthmoving equipment. Discover just how Xsite Machine Control can improve your efficiency and make certain work safety and security! Xsite Machine Control systems can be mounted to any excavator from mini excavators to big mining excavators.

Just how does machine control work? In 2D systems, the device is furnished with calibrated inclination sensing units.

The system is extremely simple to learn the fundamentals can be shown in under one hour of training. With Xsite you don't have to stress over discovering all the tips and technique at the same time. Extra training and guidelines are constantly readily available over remote support when needed. Contact This Site your neighborhood Xsite dealer to figure out more! Just how does the remote support work? A wireless net link makes it possible to establish a remote connection between the maker control system and the service facility.

Our Sheroz Earthworks Diaries

What type of information layouts Xsite systems assistance? Xsite Maker Control systems support open standard data styles, making it possible for smooth details circulation from one system to one more. Sustained data styles: 2D-Maps: DXF Factor data: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Models: DXF, XML What parts are set up on my device? Relying on your choice of system (with or without positioning, i.e - topcon laser level., 2D or 3D), your device is furnished with inclination sensors, a controller system, and a display/operating panel.

Several software and hardware services exist to help figure out a machine's present position on the earth and contrast it with a wanted design surfaceand building operators can do more to leverage the advantages. Device control is making use of different positioning sensing units and a display screen to provide the driver with a recommendation in between the placement of the pail or blade and the target quality.

Depending on the setup, device control systems can provide the driver with a simple aesthetic overview to pail or blade setting, or can automatically relocate the blade to grade by speaking with the machine's hydraulics - https://www.startus.cc/company/sheroz-earthworks. There are equipment control systems readily available for just regarding any type of maker: , dozers, excavators, dirt and asphalt compactors, scrapers, leaners, milling makers, and pavers

The 2-Minute Rule for Sheroz Earthworks

Some advantages include minimized rework, boosted task effectiveness, and reduced surveying costs. Equipment control can also help raise productivity and minimize general expenses. This technology is altering the method the building and construction industry works. Construction equipment without device control will become a thing of the past and the benefits acquired from it will be countless.

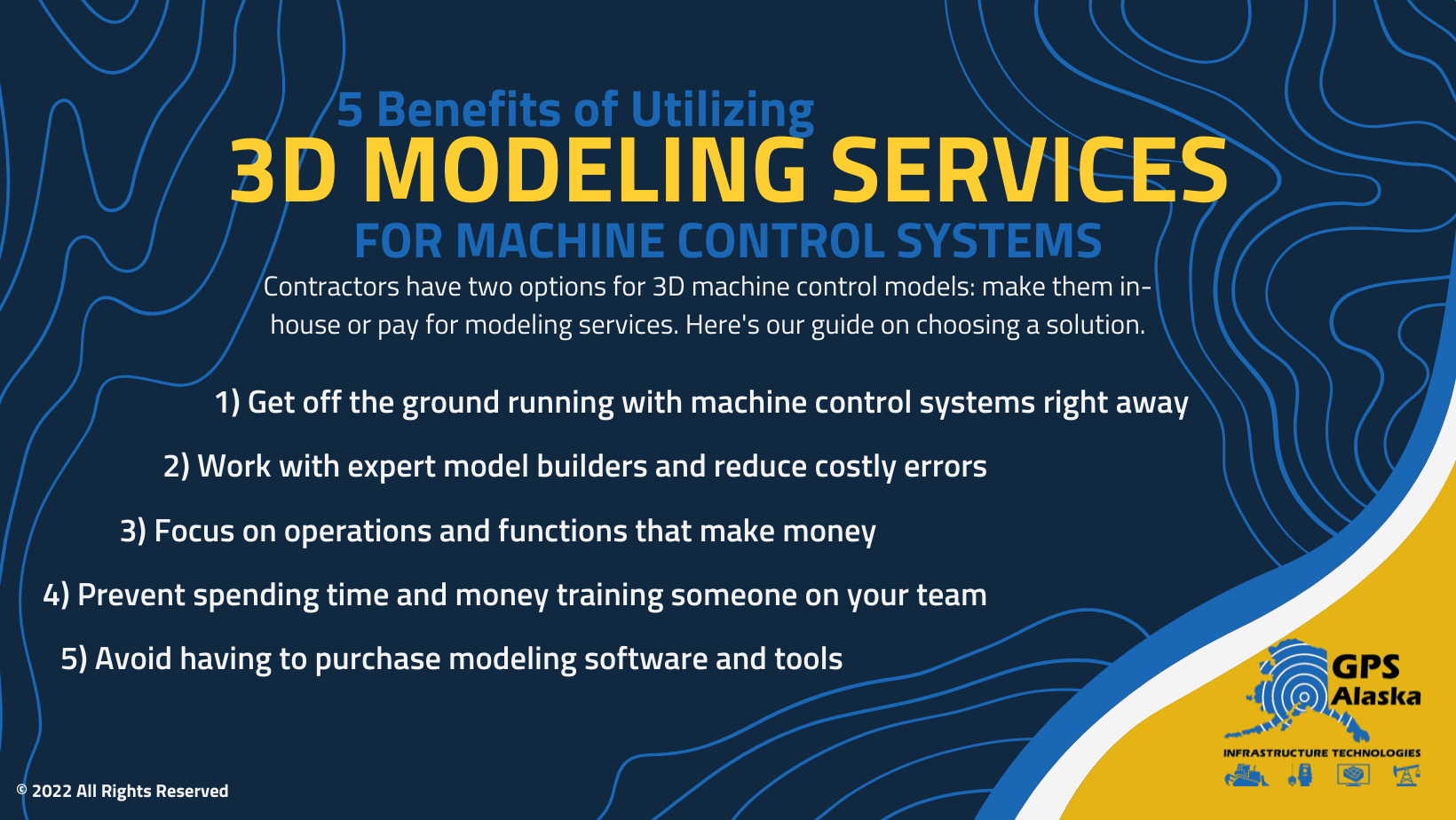

Trimble maker control systems supply a myriad of benefits to anyone that uses earthwork machinery and, at EarthCalc, we can give you with 3D declare your equipment control-enable tools. Not exactly sure if equipment control is worth the expense? Consider the following reasons why you need to consider this alternative.

Utilizing GPS aligned with your 3D layout files, these systems essentially guarantee that you will certainly get rid of or put the right quantity of material at the building and construction site. On most building and construction sites, rework is an usual and irritating truth, but with Trimble maker control, you can remove the requirement for rework.

A Biased View of Sheroz Earthworks

Commonly, with Trimble equipment control, you can get rid of excess devices at a particular work site. A job that may have needed the use of 3 or four pieces of digging deep into equipment now might require just two items of equipment to accomplish the same job in much less time. This allows you to move your equipment to one more task site and manage several work at once.

Report this page